How much do you know about ultrafiltration technology and ultrafiltration membranes?? Ultrafiltration Knowledge Points Collection, you deserve it!

How much do you know about ultrafiltration technology and ultrafiltration membranes?? Ultrafiltration Knowledge Points Collection, you deserve it!

Aug .23.2024

How much do you know about ultrafiltration technology and ultrafiltration membranes? Ultrafiltration membrane technology is an important technology for water treatment in environmental protection projects. It has extremely broad application prospects in urban sewage treatment, various industrial wastewater treatment, and recovery of useful substances. At present, one of the research directions of ultrafiltration membrane technology is to invent more efficient ultrafiltration devices, and the other is to combine it with other water treatment technologies based on the characteristics of the incoming water quality to improve the quality of the effluent.

Do you know the seven major phenomena of reverse osmosis membranes?

Do you know the seven major phenomena of reverse osmosis membranes?

Aug .22.2024

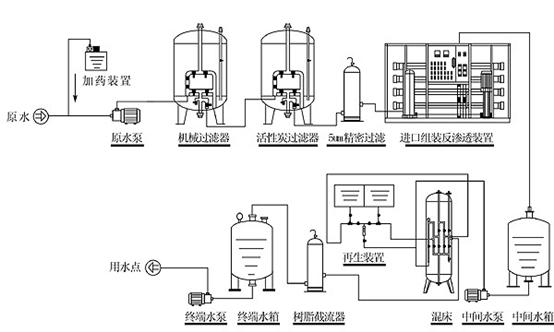

Reverse osmosis is a water treatment process that developed rapidly in the 1960s. At present, it has been used in urban water, boiler feed water, power plant boiler feed water, industrial wastewater, seawater desalination, and solute separation in various solutions. The working principle of the reverse osmosis membrane is to use pressure as a driving force to separate the solvent from the solution. It has good applications in food, electronics, medicine, printing and dyeing and other industries. In the long-term use process, some problems are inevitable. How are some of the "phenomena" that appear in the application of reverse osmosis membranes formed?

When buying a water purifier for the first time, you should know these things!

When buying a water purifier for the first time, you should know these things!

Aug .21.2024

Water purifiers are becoming more and more common nowadays. Many people want to buy water purifiers but don’t know where to start. If they buy without any advice, they will be easily overwhelmed by a lot of technical terms used by the salesperson. Today, I will tell you what these terms mean and how to “pick” the RO reverse osmosis water purifier that suits you best! Let’s read on.

How much do you know about ultrafiltration technology and ultrafiltration membranes?? Ultrafiltration Knowledge Points Collection, you deserve it!

How much do you know about ultrafiltration technology and ultrafiltration membranes?? Ultrafiltration Knowledge Points Collection, you deserve it!

Do you know the seven major phenomena of reverse osmosis membranes?

Do you know the seven major phenomena of reverse osmosis membranes?

When buying a water purifier for the first time, you should know these things!

When buying a water purifier for the first time, you should know these things!